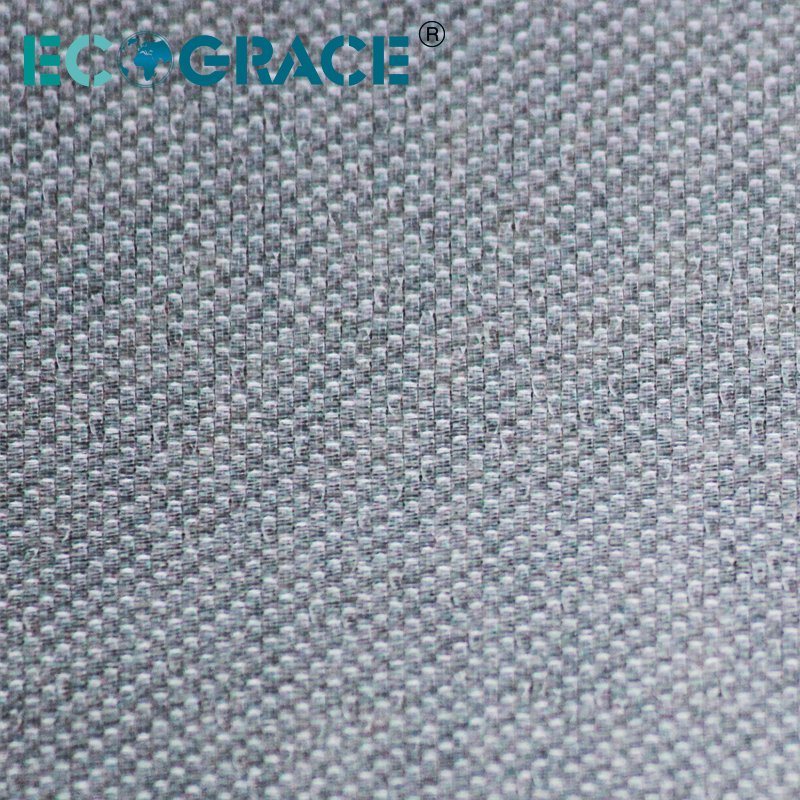

Belt filter cloth is mainly applied to horizontal belt filter, belt filter press, monobelt filter. The 95 series filter belt and double layer monofilament filter cloth is our patent products. Manufactured with special raw materials and weaving technics, the cloths have good resistence to both acid and alkali. The dimensional stability is perfect because of the special style of the strenghth, tightness, thickness and etc.

Monofilament & Multifilament filter cloth: have good air and water permeability.They have good ability to prevent the granules from blocking in the fabrics and the filter cakes can be peeled off easily, therefore, they can be used time after time.

P006MD-P140D double layer monofilament filter cloth are mainly applied to belt filters, other products can be applied to plate and frame, recessed and membrane filter presses.

Filter Press Filter Cloth : Plate and frame type, butterfly type, recessed plate cloth, chamber plate cloth, membrane plate cloth, wash plate cloth, nonwash plate cloth, flange type single pc cloth, rubber neck cloth, etc.

Accessaries : Bandages, velcro, metal eyelets, plastic eyelets, sealing felt, sealing latex, rubber neck, rubber strip, etc.

Chemical:

Catalyst, cobalt carbonate, zinc oxide, zirconium carbonate, activated carbon, cobalt carbonate, borate, dyes and intermediates, iron oxide, nickle, salt, aluminum oxide, titanium dioxide, additives, glycerol, pesticides, white carbon black, zinc, calcium carbonate, etc.

Mining:

Red mud, tailings gold, potash fertilizer, vanadium ore, the end of coal, clean coal, clay, Kaolin clay, etc.

Metallurgical:

Gold, molybdenum, lead, vanadium, nickel, zinc, copper, tungsten, carbide slag, etc.

Food

Fruite juice, suger, starch, sweetener, beer, etc.

Environmental protection:

Sewage treatment, slude dewatering, flue gas desulphurization, salt mud, fly ash, etc.

Property

Polyester (PE)

Polypropylene

Nylon

Acid

Excellent

Excellent

Excellent

Alkali

Average

Excellent

Excellent

Electrical Conductivity

Poor

Good

Average

Elongation

30%-40%

Better than PE

Poor

Recovery

Excellent

Slightly better than PE

Poor

Abrasion

Excellent

Good

Excellent

Heat Resistance

150 °C

90 °C

100 °C

Softening point

230 -240 °C

140 -150 °C

200 °C

Melting point

255 -265 °C

165 -170 °C

220 °C